Water Management

Water Containment

In certain circumstances, temporary containments (reservoirs) can be used to store multitude of items, water, contaminated fluids, contaminated soils or other media. We can use containments to create pumping reservoirs for fire suppression or live stock sustenance or transfer ponds.

For more information about containments solutions, please let us know through our contact form.

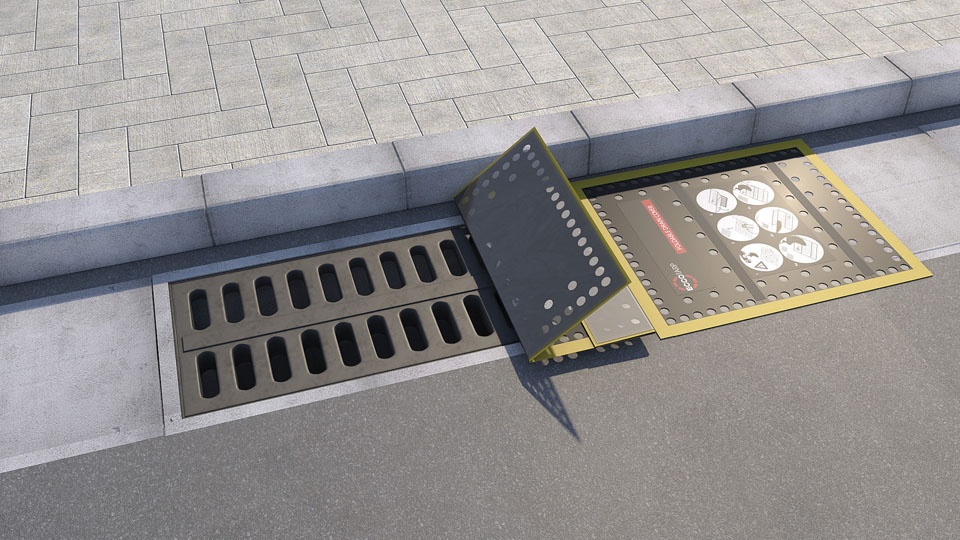

Eccotarp

Dutch Water Prevention has multiple solutions for containments, our partner ECCOTARP brand indicates a unique portfolio of products developed and manufactured by METAL ARSENAL. These are products combining metal components with plastic foils (PVC). The ECCOTARP collapsible products are highly innovative and help fire guards, rescue guards, hospital staff, during elimination of environmental accidents and spills, in logistics, in industrial warehouses, retail stores, offices, schools, etc. The ECCOTARP concentrates on the development of products to protect the environment and human health.

ECCOTARP product portfolio:

Collapsible spill berms, large customized spill berms, foldable drain covers, spill berms for pallets, sorbent dispenser carts, industrial folding funnels, large-capacity tanks and decontamination spill berms. An innovation in the production are electric rollers for fire hoses and the flexible ECCO-Barrier that can be easily assembled on the floor for separation of segments that may contain leaked liquids.

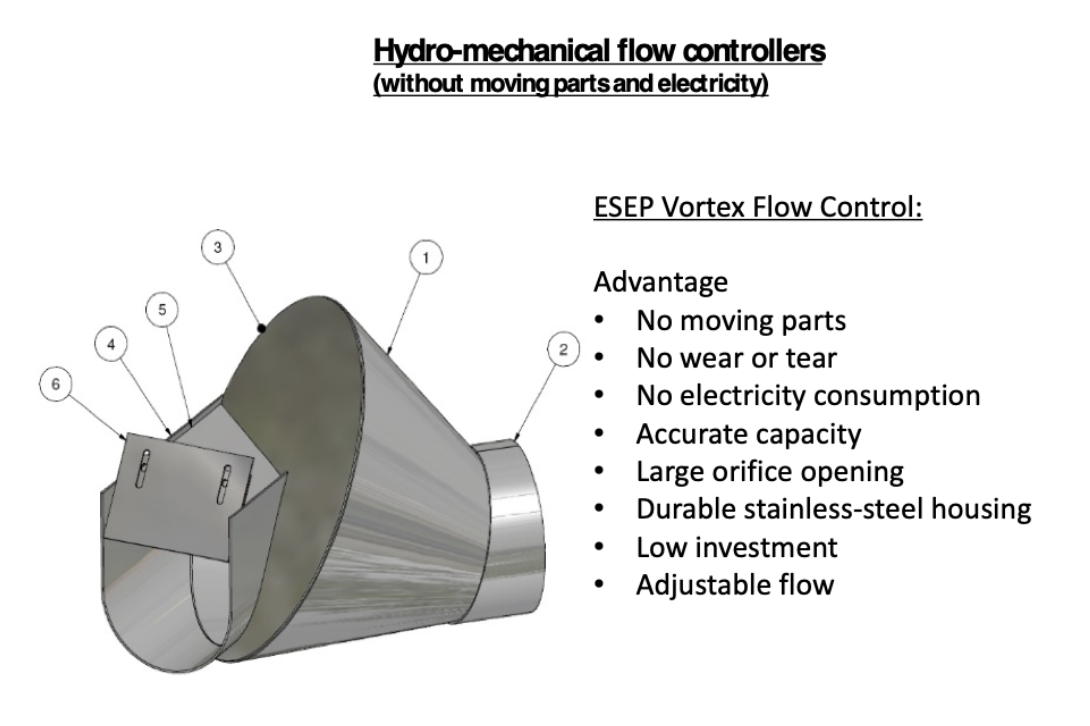

Vortex

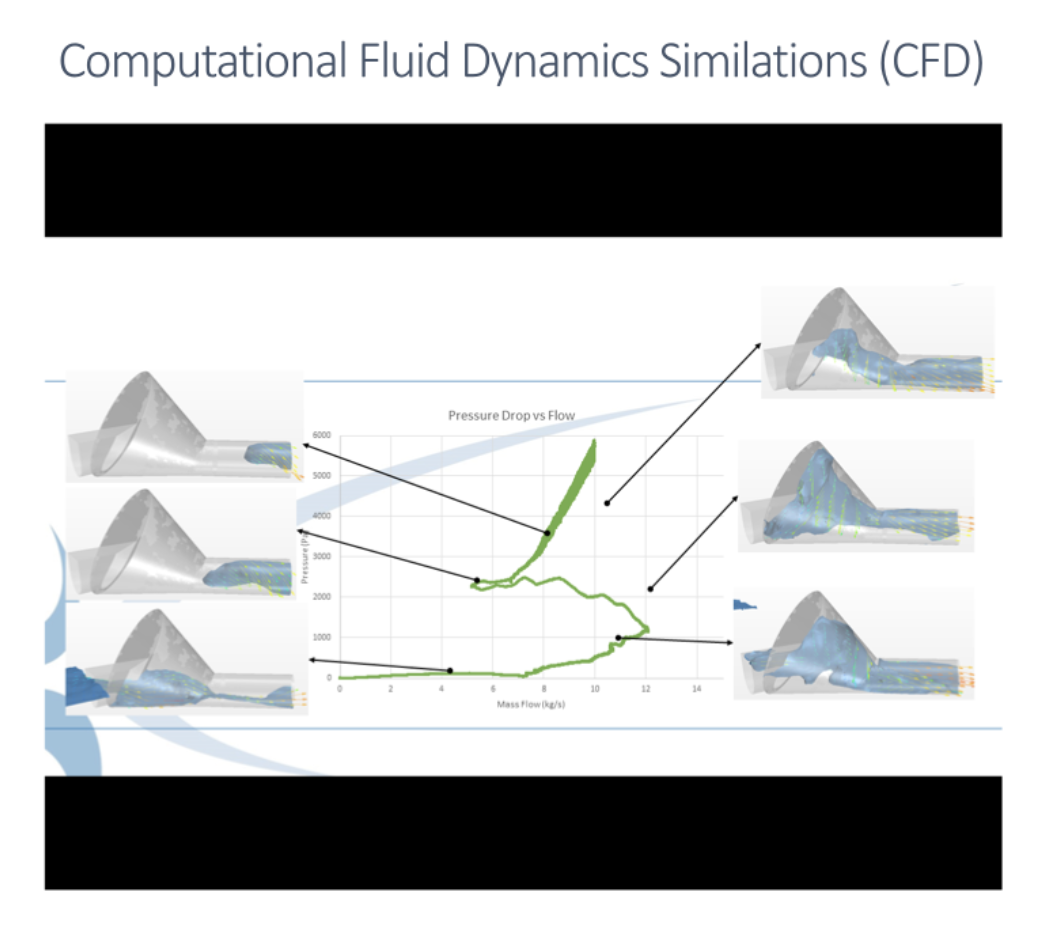

For storm and waste-water Dutch Water Prevention has the ESEP Vortex Flow Control, a unique design that restricts a flow of storm or waste-water to a certain pre-specified capacity.

The hydraulic flow characteristics are very efficient in that the capacity is relatively independent of the water pressure while maintaining a free opening.

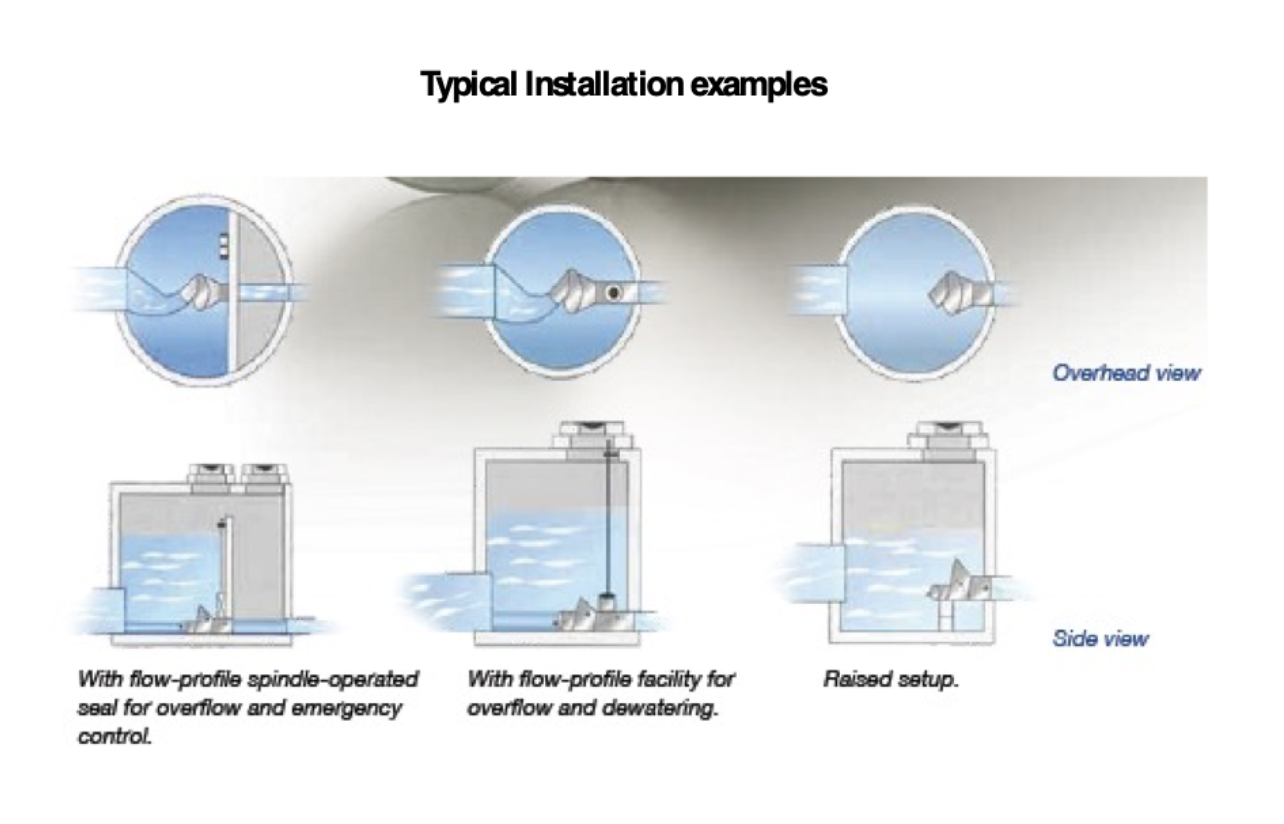

Applications:

- When there are restrictions on the maximum allowed water discharge into stormwater channels, stream, rivers, lakes, sea etc. The flow control presents an easy way to make sure maximum capacities are not exceeded with a minimum of maintenance involved.

- In any industrial wastewater treatment process: When using the flow control the flow of wastewater can be exactly specified. This way treatment plants, separators etc. do not have to be designed at peak capacities, resulting in smaller less costly treatment plants.

- To prevent city flooding due to older and smaller sewer systems. By installing the ESEP flow control at strategic locations the water is being buffered in the existing sewer pipes and therefore less likely to cause flooding.